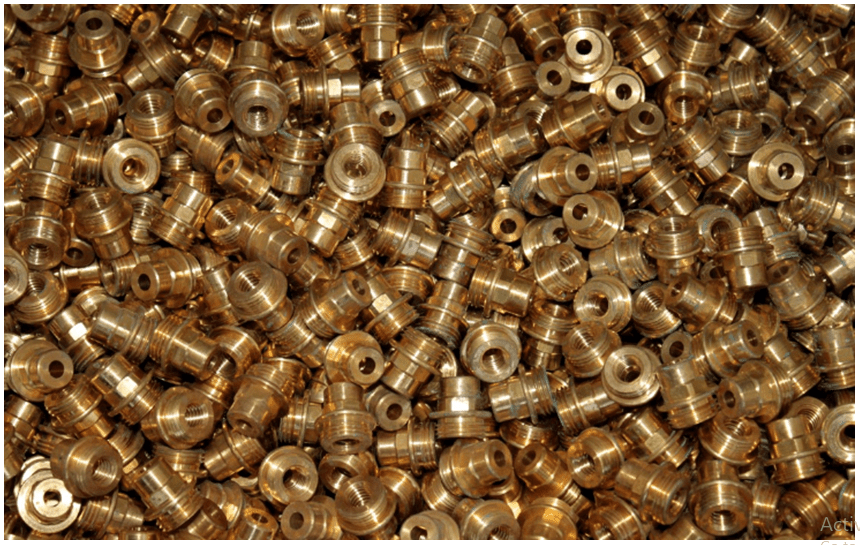

Brass is an alloy of copper and zinc used for many purposes in both domestic and industrial sectors. Knowing the composition of the brass you are purchasing is necessary because many unscrupulous elements create low-quality brass.

What is Eco Brass?

Eco brass is essentially silicon brass created with the help of lead-free casting. This brass is becoming popular nowadays because it is environmentally friendly, and it has excellent forge-ability, and machinability, and is stronger even than stainless steel.

The other benefit of this eco-friendly brass is less problem with stress corrosion cracking and dezincification.

What is Dezincification?

In adverse atmospheric and chemical conditions, the zinc in the copper starts getting leached, and this weakens the brass and this, in turn, hurts the process for which it is used. The brass becomes porous, brittle, and prone to failure due to this, in turn, weakens the brass components of any machinery or mechanical solution for which it is being used.

However, any sand-casting company that wants a c87850 certification has started using silicon-based brass, which does not use lead during the casting process. As we know, lead is a heavy metal and also toxic, making it unsuitable for the environment.

Benefits of Eco Brass

Eco brass is especially suitable for plumbing solutions and is used in many chemical factories. These factories try to source the environment-friendly brass directly from the sand-casting foundry or a dealer.

The best part about eco-friendly brass is that it does not corrode easily, and this means that you get a better return on your investment in any kind of brass machinery components. This kind of brass is becoming widespread worldwide, and many progressive foundries have started manufacturing this type of brass.